®™ Welcome to Strike Force Hobbies New Official Website. Preferred by modelers worldwide dedicated customer service

OFFICIAL BENCHVENT DISTRIBUTOR NORTH AMERICA AND CANADA !

Since Ngineering's lampshades are manufactured from aluminum and our tubing is stainless steel, these are both metals and have quite smooth surfaces. The use of CA adhesive to join these two items will work, but we have found that using a two-part clear epoxy such as Ace Quick-set 5-minute, or 2-Ton Epoxy provides a greatly superior and much more durable bond. These epoxies can be purchased from any hardware or craft store and are quite inexpensive.

This procedure assumes:

Tubing has already been shaped (procedure here).

End of the tube has been flared (procedure here).

Lampshades have had holes punched in them (procedure here).

This bonding procedure is is the same for all scales (Z through O) and for any streetlight or building light that uses our tubing and lampshades. The very first step is to ensure all parts are clean and dry. We recommend using isopropyl or denatured alcohol (not good-natured alcohol, save the scotch for other occasions). Other solvents such as lacquer thinner can also be used but they are highly toxic and highly flammable and should only be used in a very well ventilated area. The parts can be dipped in a small amount of alcohol and left on a clean paper towel to thoroughly dry. Alcohol has an affinity for water absorption so care must be taken to see that the parts have dried completely and are free of moisture.

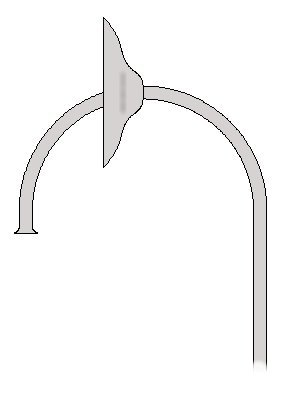

Ensure you hands are clean and free of oils and carefully slide a punched lampshade onto the unflared end of the tubing. If the lampshade was punched with the correct sized drill for the tubing being used, the shade should fit the tubing diameter very closely. Take your time placing the shade on the tube so as not to squeeze and distort shape of the shade. Slide the shade along the tube length and work it up and around the curved portion of the tube until the shade is positioned half way around the final curve of the tube. See Figure 1 below.

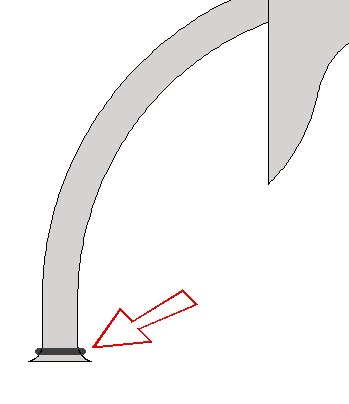

Carefully clamp the tubing in your bench vise by the straight portion, if building a streetlight, or by the portion that will go through the building if constructing a building light such as a gooseneck lamp, and adjust the tubing so it is perfectly vertical (if a streetlight) or horizontal and straight (if a building light). This is very important because once the epoxy is applied and the shade is in position, making sure everything is level and square has to happen before the epoxy cures. The vise only needs to secure the tubing enough to keep it from moving while applying the epoxy and positioning the lampshade. Over tightening can easily deform the tubing.

Mix a small amount of epoxy according to the manufacture's guidelines (usually equal parts of resin and catalyst), and using a sharpened toothpick, apply a small bead around the tube end just above the flare. Important: Do not use too much epoxy, once the shade is down in position, excessive epoxy can flow into the open end of the tubing. This would not be a good thing. See figure 2 below.

Now the shade can be lowered down onto the flared end of the tubing as shown of figures 3 and 4 below. Make sure the shade is all the way down so that the bead of epoxy flows around the top of the underside of the shade where the flare is.

Now, before the epoxy starts to cure, inspect the levelness of the shade. It is very important that the straight portion of the tube is aligned vertically (reinspect its position side-to-side and front-to-back). If the shade is tilted, adjust it so that it looks level and set this assembly aside to cure thoroughly.